Skip to content

Have you ever wondered if ethical manufacturing processes were used when making your bedding?

Here at Brolly Sheets, it’s a topic we take seriously. With “Made in China” means so many things, we’re determined to explain what makes our product manufacturing process better.

The expertise of our team in China, the top quality materials they use and their superb working conditions result in a product we’re incredibly proud of.But this doesn’t come cheap, and we’ll be the first to admit, that we’re not the cheapest. We think that paying a few extra dollars for your Brolly Sheets bed protectors is worth the investment, and today we’re going to explain why.

How Brolly Sheets Take Ethical Manufacturing Seriously

Before I started Brolly Sheets, I thought all factories were the same. I’ll be honest: the factories and their workers weren’t even on my radar. But after 12 years in the business, I know a lot more.

Let me paint you a picture.

Firstly – the difference between a country factory and a city factory.

China is a country full of huge cities. There are cities you have never heard of, but they’re so huge they have populations of over 10 million people. You’ll find the majority of factories located in these large factories, and they provide dormitories for their workers to live on site in. That’s because travelling home is too expensive and too far a distance for workers to travel daily.Sadly, the workers (mostly women), are only able to travel home twice a year during the holidays.

The Brolly Sheets factory is in a small country town when the women (and a couple of men) can go home each night to their families.

On my last trip, the entire team and I went out for dinner.

Secondly - Piece work vs pay per day

In China and other developing nations, most workers get paid per piece that they complete. This means they work quickly to finish as many as possible. This results in quality levels dropping and an unpleasant work environment.

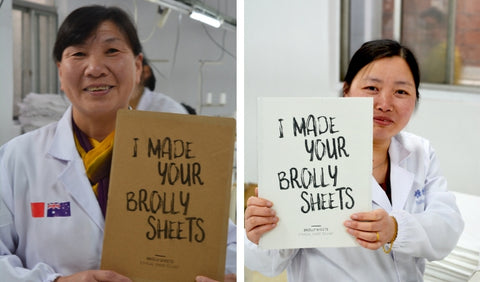

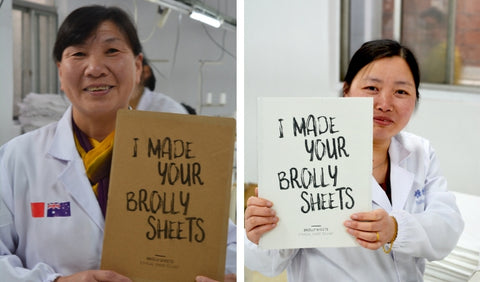

The team who create our Brolly Sheets products in China are paid per hour of work, just like the team here in NZ. It’s important to us that there is time in the day for people to laugh and chat with each other.

Thirdly – Factory conditions

Sweatshops come as no surprise to anyone, with the media having shown many over the years. The working conditions are horrifying, to put it bluntly.

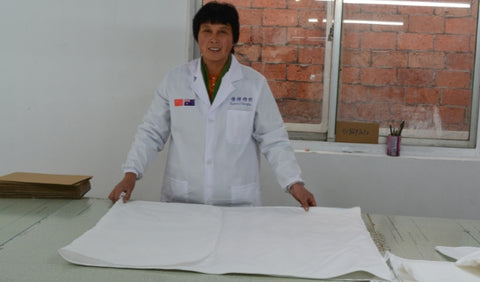

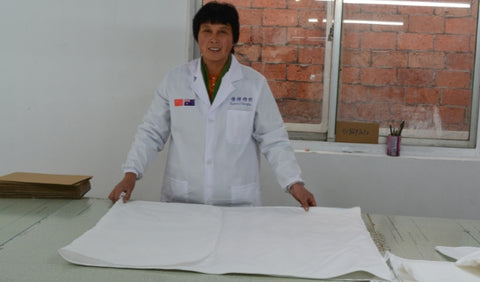

This isn’t the case for the Brolly Sheets factory though. It is small compared to others in China, but the buildings themselves are large, well-lit and incredibly clean. The sewing machines are well spaced out, and each worker has a lot of space around their workstation. Packaging occurs in a separate room and I’m impressed with the space afforded to workers and their jobs.

Folding each Brolly Sheet to fit in the packaging is like doing origami.

Lastly – Family

For over 10 years, James and I have been doing business together. Our families are important to both of us, and together we have grown our businesses. A Chinese tradition is the taking of a European name and I have been asked to give both James’ daughters an English name (Catherine and Lily). It’s an honour which was bestowed on me.

James’s sister heads up the machinists and his Dad is there every day making the team lunch.

So, we will never be the cheapest, but the Chinese Brolly Sheet team are well looked after. Our product quality is superb, that they are passed around the family instead of going to the landfill.

Buy once and buy well.

Diane